Regardless of type, size, or simplicity of operation, the proper management of all decentralized wastewater systems is critical to reliable performance and sufficiently long useful service lives. Because most of the components of individual or clustered decentralized wastewater systems are buried, it is very easy for property owners and users of these systems to feel “out of sight, out of mind”, until a problem occurs. And unfortunately, by the time many problems “surface”, they can be very expensive to fully repair. Just as it is with health care, a certain amount of routine preventive care and maintenance for decentralized wastewater systems can result in substantial savings over time.

There are a variety of decentralized wastewater management “models” around the U.S. and elsewhere that have been implemented, each with differing degrees of involvement by public entities and property owners. The simplest models rely primarily on property owners for the care of systems. Due to the tendency of property owners to ignore routine maintenance until a problem arises, this approach has typically had less success than other models that rely to a greater extent on the involvement of public entities and regulators with more knowledge and experience with the care of systems than the average property owner. Such basic management activities as periodic inspections and pumping of septic tanks can avert serious problems and costs. In some cases, proper management of a system may involve multiple site visits by a qualified service provider, or the collection of effluent samples from the system to verify proper performance.

As development continues in increasingly populated areas around the world, the use of sites with more challenging physical characteristics increases also. In short, the sites with the best overall building conditions tend to be used first. As sites with steeper slopes and/or shallow or unsuitable soils are used, and with the need to provide for appropriate levels of public and environmental health protection in all locations, the complexity of design and operation of systems has tended to increase. Decentralized systems with increasingly sophisticated design have become relatively commonplace in many parts of the U.S. where there are different types of challenging geophysical conditions. For individual residences and small commercial facilities, some systems have become commonly used for adverse site conditions in some areas of the U.S. that may cost less initially to install, but which have excessive operation, maintenance and repair costs over time.

CES works with clients to evaluate options suitable for their particular site conditions with management needs in mind. We understand that most property owners prefer systems that require as little routine maintenance as possible, with accompanying low long-term costs and problems.

No matter what type of management model and regulatory requirements for management pertain to a particular political jurisdiction, it’s critical for property owners to insist that their decentralized wastewater system be designed and constructed for proper functioning, and to allow for the maintenance and/or repairs that will be needed over time. This involves attention to many aspects of the system, including:

- Ready access to system components that will need inspection, maintenance, and or repair periodically;

- Use of components and materials that tend to function very reliably over long periods of time, and which are relatively easy to service if needed;

- Making sure that systems are installed in accordance with applicable plumbing and electrical codes;

- Water-tightness of all parts of the system from which entrance or exiting of surface or ground water must be prevented, including tank risers and lids;

- Locating system components appropriately relative to site activities (For example, not placing a subsurface effluent dispersal field where the property owner wishes to surface irrigate a lawn or landscaped area);

- Obtaining good as-built drawings from the designer of the system after construction, along with clear operation and maintenance procedures; and

- Making sure that a service provider is available who is licensed and qualified to perform the maintenance needed for the system.

These are just a few considerations in the design of a system that lends itself to sound management over time. CES routinely considers these and other more complex engineering factors when working with clients on the selection of good wastewater service solutions. Below are examples of some of these management concepts.

1. Below is a photo of a portion of an intermittent sand filter system (located in the raised bed on the left) to provide enhanced treatment of the effluent prior to final subsurface dispersal in a low-pressure dosed field area in the yard. The green riser lids adjacent to the sidewalk cover watertight risers that extend to the ground surface from the septic tank and a pump tank. The lids are watertight, and are bolted down using a specialized tool, to help prevent unauthorized entry. The green color of the lids tends to blend well with surrounding vegetation. Bringing the covered risers up to grade in this way allows for easy access to the system as needed without having to dig up yards or landscape vegetation, and helps prevent soil and other material from falling into the tanks when they need to be opened for periodic pumping or inspection.

The above photo shows the risers installed on tanks for a different system prior to placing the final soil cover.

2. Note in the three photos below the valve covers with green removal lids used to cover some of the smaller valves used in these systems. Note also in the middle and third photos the green locator tape used for the buried pressure lines. These types of simple features allow for locating and servicing critical system components after the system is buried. The effluent distributing valve in the third photo is covered using a green bolt-down lid of the same type as is used for the septic tank or pump tank, and requires a specialized tool for the bolt head.

3. Note in the photo below of the effluent pump station that the pump discharge lines for the two pumps located in the vault are labeled #1 and #2, to identify the pumps for the control panel and for the field dosing areas. Failure to properly label controls and basic system operational components can lead to needless time losses and expenditures in locating and correcting problems. Also note the U-shaped PVC handle on the effluent filter vault adjacent to the pump discharge lines. The handle allows for easy removal of the effluent filter for inspection and cleaning as needed. Also visible is the wiring box at the bottom of the photo which is sealed with a screw-down lid to keep moisture and corrosive gases away from the pump control wiring.

4. The photo below of the large subsurface low-pressure dosing field shows the screw-on PVC caps on the ends of each lateral line turn-up, allowing for flushing of field lines as needed. The final soil cover will be just a few inches above the end caps, and the lines can be located using metal detection tape that is buried along manifolds and selected lateral lines.

5. Subsurface effluent dispersal fields should have well established vegetative covers of a type suitable to the particular type of dispersal system. This allows for uptake of moisture and nutrients from the effluent, and prevents soil erosion from the dispersal field. Below is a photo of a final grass cover over a low-pressure dosed dispersal field in a large state park.

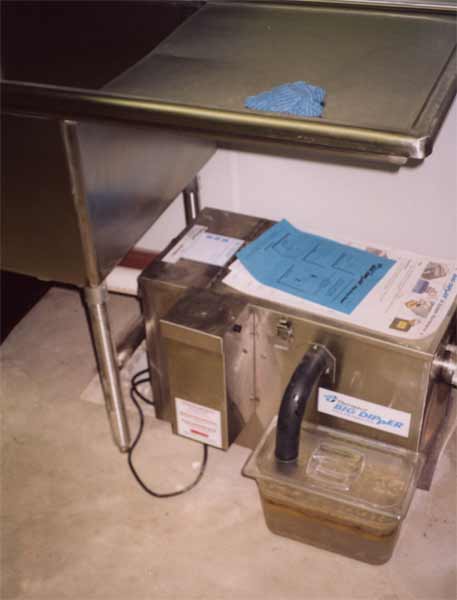

6. Proper management of oils and grease from restaurants and commercial kitchens is always of concern. Grease removal can be addressed in a variety of ways in the system design, depending upon the particular system and applicable regulatory requirements. However, almost all grease management processes require proper removal and disposal of oils/grease waste. The photo below shows one type of automated commercial kitchen grease skimming unit installed below a kitchen sink. The skimmed grease is removed daily or as it builds up, and placed in an appropriate enclosed unit for subsequent grease recycling or disposal. This type of skimming unit can greatly reduce the oils and grease loading to a septic tank, and thus decrease the needed capacity to achieve good primary treatment.